A Q&A with Functional Prototypes Expert Jacob Turetsky

This month’s Spotlight focuses on Functional Prototypes, the working, testing, problem-revealing models that turn ideas into something you can actually use. Functional prototypes rarely look polished. In fact, they often look wrong. But for Jacob Turetsky, that’s exactly the point. In this Spotlight interview, Jacob reflects on why functional prototypes matter, how they shape better products, and why failure when designed intentionally can be the most valuable outcome of all. In this conversation, he shares his process, his philosophy, and why functional prototypes are the backbone of meaningful product development.

Q:

Can you describe a moment when functional prototypes failed so clearly that it completely changed the direction of a project?

A:

While working at a large ergonomics-focused product company, we were developing a stacking chair that included a subtle amount of active recline. The idea was to rely on the frame of the chair itself to create that movement, without adding a complex mechanism.

I quickly built a prototype using CNC plywood panels to mimic a kind of spring action happening in the lower corner of the chair leg. Structurally, it made sense. But no matter what we did, every time someone leaned back, it would pull their shirt out of their pants if it was tucked in.

It turns out that recline needs to happen as close as possible to the human hip, which is difficult because that’s exactly where your body is already sitting. Our pivot point was dramatically far from where it needed to be. Even though it worked from a construction standpoint, it completely failed ergonomically.

That prototype forced us to abandon the idea of relying solely on the frame. We moved to more complicated mechanisms that brought the action closer to the body. We built another prototype that had a cluster of potential pivot points in the right region, full of holes and adjustable pins. We could move things a quarter inch at a time and test them with people.

It didn’t look like a finished product at all. It was messy and riddled with holes. But only after that process could we move forward and actually design the chair.

Q:

For readers who may not be familiar with the term, how do you define a functional prototype? What separates it from a model or visual mockup?

A:

To me, a functional prototype is about answering the riskiest questions as early as possible—when those questions are still cheap and easy to fix.

Every design has assumptions. A functional prototype lets you isolate those assumptions and test them before you layer on additional detail. It’s not about surface or appearance yet.

You’re looking at how components relate to each other, how the user interacts with the system, and whether the overall architecture works. Drawings and visual models can only take you so far. When you need to know how something actually feels, moves, or behaves, you have to build it.

Q:

Why are functional prototypes so critical, especially in hardware, wearables, and integrated systems?

A:

Design is hard. And the design process really demands that we get answers to the riskiest questions early.

Functional prototypes allow you to test assumptions when it’s still okay to pivot—when changes don’t feel like mistakes or failures. You’re able to ask, “What are we testing right now?” and “How many versions should we build?” before committing to anything expensive or overly refined.

That’s what functional prototyping is about for me. It’s figuring out how things relate—between components, between the product and the user—before worrying about how it looks.

Q:

What makes functional prototypes successful?

A:

The most important question is whether it gave you the answer you needed.

A successful functional prototype is very well scoped. If something isn’t being tested, it should be over-engineered so it doesn’t interfere with the result. You don’t want flex or instability in one area creating a “mushy” feeling somewhere else and confusing the outcome.

I actually think one of the most boring outcomes is when a prototype works exactly as expected and doesn’t reveal anything new. A good prototype should teach you something—ideally something unexpected.

Q:

You’ve worked across design engineering, product development, and hands-on prototyping. What first drew you toward making things work in the real world?

A:

It’s hard for me to point to one specific moment. It really feels like a chain of experiences mixed with some luck.

I grew up building things and tinkering. Early on, I wanted to be a car designer, which led me to industrial design and then to furniture. I had a furniture internship that went badly—I had a severe allergic reaction to exotic wood and realized I didn’t want to be milling cabinets every day.

At the same time, I was working on a medical design project at Pratt, and that completely shifted my perspective. I loved the process of taking an idea, pinning it up, building on someone else’s thinking, and then making something that actually assembled and functioned.

Suddenly, we were creating things that had never existed before. That was far more interesting to me than just building objects. I still build things with my hands, but now it’s more of a hobby. What really captured me was thinking through how mechanisms work and why one approach works better than another.

Q:

Looking back, what experience most shaped your approach to prototyping?

A:

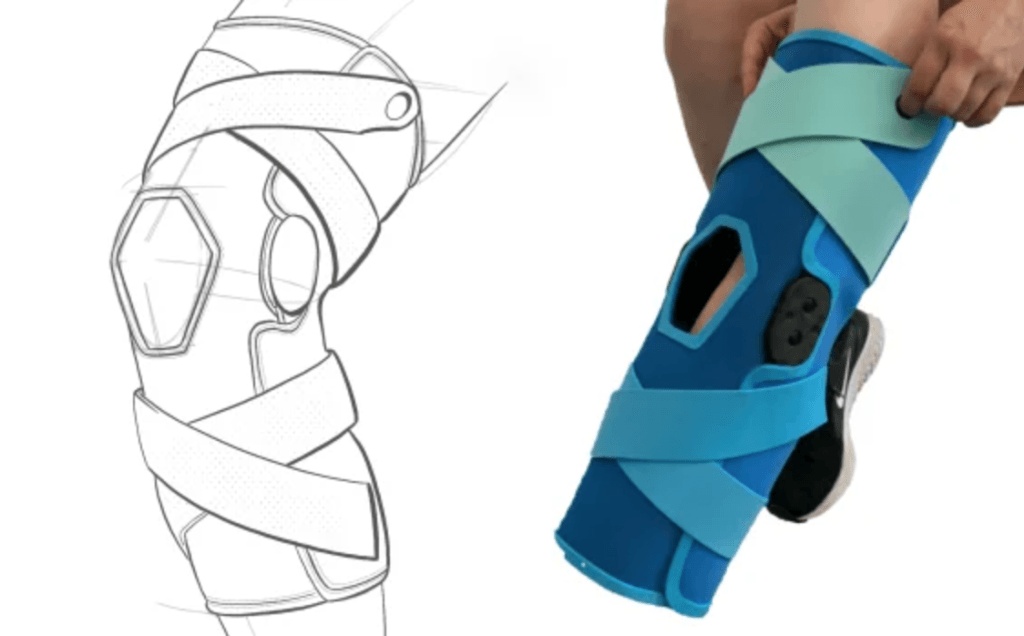

Early on, I learned that designing a prototype is often separate from designing the final product.

Sometimes you need a prototype that’s adjustable. You need to test different lengths, pivot points, or ranges of motion. In environments where the work is mission-critical and function-first, prototyping becomes central to the design process because you can only learn so much from drawings or static models.

I remember working on a mobility device where everyone had different ideas about wheel placement and handlebar positions. We built a single, highly adjustable prototype using basic extrusions so we could test all of those ideas in one model.

That experience reinforced something I still believe strongly: functional prototypes don’t need to be beautiful, but they do need to be neat, intentional, and well thought through. In many ways, a functional prototype is its own design.

Q:

When starting a project, how do you go from an idea to a working prototype?

A:

I really trust the design process. I usually start by defining what I call the architecture of the product. That means stepping back from materials and finishes and asking more fundamental questions.

Is it vertical or horizontal? How do the components relate to each other and to the user? I try to answer the biggest questions first and then work inward, narrowing the scope as I go.

I’ve learned that trusting this process is far more reliable than waiting for a single stroke of genius. It’s also much more valuable to clients because it creates clarity early on.

Q:

You often work in environments where time is short and the stakes are high. How do you decide what “level of fidelity” is right for each stage of prototyping?

A:

A lot of it comes down to education. Some clients see a prototype that doesn’t work as a failure, so part of the job is framing prototyping as learning.

I always imagine being in the room when the prototype doesn’t work. If I’d feel embarrassed, then it’s too expensive or too high-fidelity for that stage. At that point, I’d rather rewind a week and build two cheaper versions.

Q:

How do you avoid perfecting things too early—or too late?

A:

It’s about knowing where you are in the process and what questions you’re supposed to be answering at that moment.

If your first prototype is machined out of aluminum, you’re in trouble. If it lights up and moves and does everything at once, you’ve gone too far. Early prototypes should be cheap, fast, and iterative.

Letting time, materials, and scope set boundaries is important. Those constraints help you avoid over-investing before you’ve learned what you need to learn.

Q:

You’ve collaborated with designers, engineers, and researchers. What makes a cross-disciplinary team successful when you’re building prototypes under real-world constraints?

A:

On cross-disciplinary teams, I often act as the hub. It’s important to let subject-matter experts focus on what they do best, but designers also need to advocate for the user.

You don’t need to become an expert in everything, but you do need to learn enough of each discipline’s language to collaborate effectively. Ultimately, the designer’s role is to fight for the human experience and make sure the system works for the person using it.

Q:

Looking ahead, what skills or mindsets will the next generation of prototypers need most?

A:

With tools like 3D printing, it’s very easy to add detail too early. You have to learn when to stop.

Print it. Test it. Move on. Don’t keep refining something in CAD just because you can. Earlier in my career, tools naturally limited how far you could go. Now you have to create those limits yourself.

Functional prototyping is about answering questions quickly—about getting things to work or not work as fast as possible. That mindset is more important than any single tool.

—

Check out the rest of our Spotlight series to hear more from leaders in the design industry. Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!