Building Ideas: The Role of Conceptual Mock-Ups in Soft Goods Design

Thinking in Three Dimensions

Design rarely happens in a straight line. In soft goods design, where products must conform to the body, support movement, and feel comfortable in real-world use, mock-ups are especially crucial. Subtle differences in fit, tension, or material behavior can completely change how a garment or wearable feels, yet these nuances are often invisible in drawings or CAD renderings. Rough 3D models allow designers to evaluate ergonomics, assess how straps, seams, or closures interact with the body, and ensure that the product performs intuitively and comfortably before a higher fidelity prototype is made.

While drawings and digital files are powerful tools, they can only go so far. Sometimes the only way to know whether a curve feels natural in the hand, a hinge aligns with joint movement, or a strap sits comfortably across the body is to build it in the real world, however roughly. That’s where conceptual mock-ups come in. These early, low-fidelity models aren’t meant to be polished or permanent; they’re tools for thinking. They expose hidden challenges, spark unexpected directions, and make the abstract tangible. Just as importantly, they allow both designers and clients to engage with an idea in ways that are more intuitive than a flat image or diagram could ever provide.

At Interwoven Design, we see mock-ups as a bridge between imagination and execution. Building in 3D is how we explore questions that sketches can’t answer, and it’s how we make sure our concepts are grounded in the realities of human use. For us, mock-ups aren’t just a stage in the process; they’re an act of curiosity, iteration, and craft that defines how ideas come to life. In this Insight article, we’ll discuss the value of mock-ups, outline various methods of making them, and share three case studies of studio projects that showcase the ability of mock-ups to elevate the design process at every level of fidelity.

Why We Build to Think

Design is, at its core, a process of discovery. Even the most carefully considered sketch or digital model can miss details that only emerge when something is built in physical space. By working in three dimensions, designers invite surprise into the process, sometimes confirming assumptions, other times revealing issues that couldn’t have been predicted on paper.

Conceptual mock-ups are powerful because they shift the question from “Does this look right?” to “Does this work in real life?” A quick foam cut-out can reveal that a button is too far for the thumb to reach, or that a curve looks elegant in renderings but feels awkward when held. Fabric mock-ups can show how material drapes, stretches, or resists movement, helping teams anticipate comfort and durability before investing in higher-fidelity prototypes.

Just as importantly, building early and often keeps the design process agile. A mock-up doesn’t have to be precious; in fact, its roughness is part of the point. The less time invested, the easier it is to test, critique, and move on. This freedom encourages exploration rather than perfectionism, giving space for bolder ideas to emerge and evolve.

At Interwoven Design, we use mock-ups not just to validate concepts, but to provoke questions. What happens if this element shifts by an inch? How does the design change if the material is softer, stiffer, lighter? Every build is a chance to learn something new, and often those discoveries become the foundation for the next round of design.

Methods of Mock-Up Making

There’s no one right way to make a conceptual mock-up, only the method that best suits the question at hand. Also, we never make just one! Sometimes the goal is to understand form and scale, other times it’s about testing flexibility, ergonomics, or how a feature behaves when it meets the body. Because of this, the process often spans a wide spectrum of materials and techniques, from the scrappiest cardboard approximation to precision 3D prints.

Paper and Foam Models

When speed matters, nothing beats the simplicity of paper, foam, or cardboard. These materials are quick to cut, shape, and tape together, allowing designers to test proportions, angles, and spatial relationships in minutes. They’re the fastest way to move an idea out of a sketchbook and into the real world. At Interwoven Design, we love paper as a tool, as it behaves a lot like a textile.

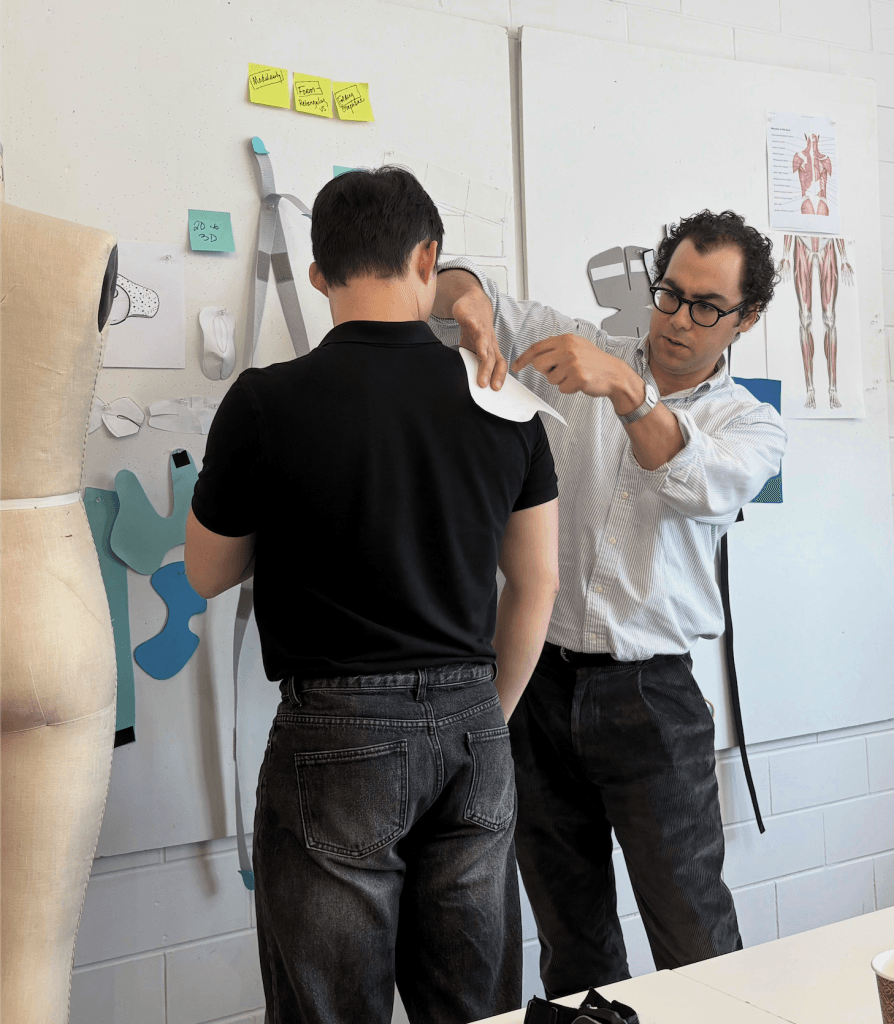

Fabric and Soft Goods Constructions

For wearables or textile-based products, mock-ups made from muslin, mesh, or other inexpensive fabrics can reveal how a design drapes, folds, and moves against the body. These rough-sewn models often expose ergonomic insights that drawings can’t capture, like how a strap pulls across the shoulder or how a pocket can be accessed in motion.

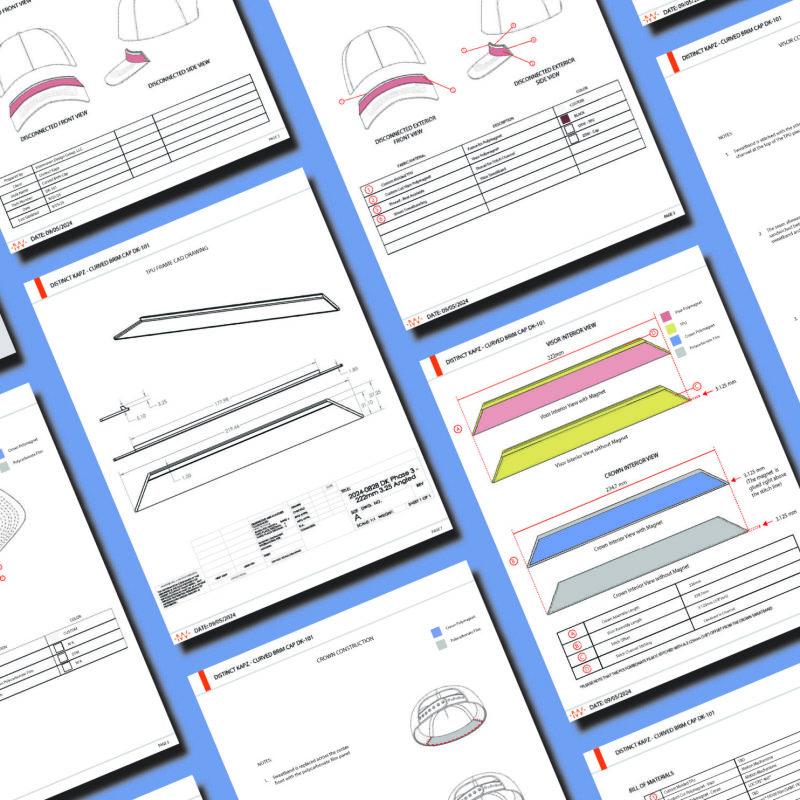

Digital-to-Physical Hybrids

Sometimes, precision is the priority. Tools like 3D printing, laser cutting, or CNC machining allow teams to translate digital models into physical parts with exact dimensions. These methods are especially valuable when testing components that interact mechanically or when verifying that multiple parts fit together as intended. Like the design process itself, mock-up making is rarely linear. A paper sketch model may inspire a fabric iteration, which then sparks a 3D-printed test. Each build answers some questions while raising others, creating a feedback loop that moves the design steadily closer to resolution.

At Interwoven Design, we embrace this iterative mix—shifting tools and materials as needed to keep ideas moving and evolving. We are nearly always combining soft goods and hard goods in the same product, and we use a range of construction methods to build the components needed to test the interaction between the two.

Mock-Ups as Communication Tools

Mock-ups are more than internal design aids, they are powerful tools for communication. A sketch can suggest form, and a CAD file can demonstrate function, but nothing replaces the clarity of a physical object. When stakeholders can hold, wear, or manipulate a mock-up, abstract ideas become concrete. The conversation shifts from speculation to lived experience.

For clients, this means gaining confidence that the product is on the right track. Engineers can assess feasibility, materials, and assembly details. Users, meanwhile, provide feedback that is grounded in the reality of use rather than imagination. Each group engages with the same artifact, but through their own lens, creating a richer and more specific dialogue.

This shared understanding is critical. By aligning expectations early in the process, mock-ups reduce the risk of costly misunderstandings later. Questions of scale, ergonomics, or usability are resolved in the physical world rather than in post-production fixes. In this way, mock-ups not only accelerate collaboration but also protect both the integrity of the design and the efficiency of the project timeline.

Case Studies: Mock-Ups in Action

Case Study 1: The Breg CrossRunner™ Soft Knee Brace

When Breg set out to reinvent their soft knee brace line, they partnered with Interwoven Design to merge engineering precision with human-centered comfort. The challenge was to create a premium brace that could address a wide spectrum of injuries and instabilities while remaining easy to use, breathable, and adaptable to different body types.

Early in the process, mock-ups played a critical role: foam models and fabric constructions allowed the team to explore how hinges aligned with anatomy, how straps wrapped and adjusted, and how materials compressed or released tension in motion.

These quick builds revealed insights that sketches alone couldn’t capture, helping refine ergonomics, donning sequences, and user comfort long before committing to a final design direction. By iterating through mock-ups, the team established a design language that balanced sleek aesthetics with technical performance. The result, the Breg CrossRunner™ Soft Knee Brace, exemplifies how physical mock-ups can bridge vision and execution, ensuring that every detail—fit, function, and feel—was tested and validated in three dimensions.

Case Study 2: The Perci Emergency Preparedness Vest

When INVICTA Ready set out to design a product that could help families face the growing threat of natural disasters, they partnered with Interwoven Design to create something intuitive, wearable, and life-saving: the Perci Emergency Preparedness Vest. The challenge was complex: developing a garment that could store and organize critical supplies, remain comfortable during rapid evacuations, and be universally adaptable across diverse users.

Early mock-ups were essential in shaping the vest’s design: muslin and fabric prototypes allowed the team to test how tools and essentials could be organized into categories, ensuring each pocket was ergonomic, accessible, and balanced against the body.

These rough builds revealed whether wearers could move freely—carrying a child, lifting luggage, or running—without being restricted by bulk or weight distribution. These iterative mock-ups uncovered design insights that made the vest both practical and confidence-inspiring: reflective icons and graphic labeling clarified what each pocket contained, while ergonomic patterning and stretch panels improved comfort and mobility. The inclusion of a collapsible hood, internal storage systems, and integration with a companion mobile app extended its functionality, making the vest a true system for preparedness rather than just a garment.

Recognized internationally, the Perci Vest won Gold in Industrial and Life Science Design – Safety Designs and Bronze in Design for Society at the 2022 International Design Awards (IDA). The project underscores the value of mock-ups as more than just prototypes: they were the means of simulating real-world scenarios, uncovering challenges, and validating design decisions. For the Interwoven Design delivery team, building in three dimensions was the key to transforming the abstract concept of “preparedness” into a product that is intuitive, wearable, and empowering in moments of crisis.

Case Study 3: The HeroWear Apex Exosuit

Warehouse work places enormous strain on the body. Long shifts, hot environments, and constant bending and lifting often leave workers fatigued and injured, especially in the lower back. When a team from Vanderbilt’s Center for Rehabilitation Engineering & Assistive Technology developed a proof-of-concept for a mechanical exoskeleton, they partnered with Interwoven Design to transform their idea into a fully commercialized product: the HeroWear Apex Exosuit. Mock-ups were central to the exosuit’s design process. Our delivery team built garment and hardware mock-ups to test placement of mechanical components, optimize body heat management, and fine-tune ergonomics in real time.

Dozens of soft goods mock-ups were created and tested, shaping the design’s modular fit system, strength adjustability, and range of motion. By iterating through muslin mock-ups to increasingly high fidelity prototypes, the team ensured that the exosuit was not only effective in reducing strain but also intuitive and comfortable enough to gain worker acceptance, an essential factor for adoption on the job floor.

The final design balances technology with wearability: lightweight, breathable, and easy to don and doff, the Apex relieves more than 50 pounds of strain from the lower back. Its garment-based system manages body heat while remaining easy to clean and maintain, enabling daily use in demanding environments. The Apex Exosuit has been celebrated internationally, winning Gold at the 2021 IDEA International Design Excellence Awards (Commercial & Industrial), Platinum at the 2020 Spark Design Awards, and recognition as a 2021 Core77 Design Awards Notable winner (Commercial Equipment). These honors highlight not only the strength of the final product but also the value of mock-ups and iterative design in transforming breakthrough research into a scalable, worker-centered solution.

Building Toward Better Ideas

In soft goods design, mock-ups are more than a step in the process, they are essential to understanding how a product interacts with the body. They transform abstract concepts into tangible experiences, allowing designers to evaluate fit, tension, mobility, and comfort in ways that sketches or digital models alone cannot. This hands-on approach fosters a studio culture of experimentation, openness to failure, and playful discovery, while balancing intuition with practical constraints.

At Interwoven Design, building mock-ups, whether for wearable braces, ergonomic vests, or modular exosuits, brings ideas to life, revealing hidden opportunities and guiding iteration. By seeing, touching, and testing concepts in three dimensions, we ensure that every soft goods product is not only functional and durable, but also intuitive, human-centered, and aligned with real-world use. In short, making shapes the trajectory of design, producing solutions that resonate with both people and their bodies.

Interwoven Design is a design consultancy that is positioned at the intersection of soft goods and wearable technology, creating products that function with the body and offer comfort as well as the superb performance that arises through the innovative incorporation of rigid, often electronic and responsive elements. Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!