Designing for Manufacture: Inside the Soft Goods Tech Pack

From Concept to Creation

Every great product begins with a spark of creativity—a sketch, a mood board, a prototype. But in order for that idea to become a physical object, it needs more than inspiration. It needs precision. Technical design is the step that translates vision into manufacturable reality, turning abstract concepts into clear instructions that factories can execute.

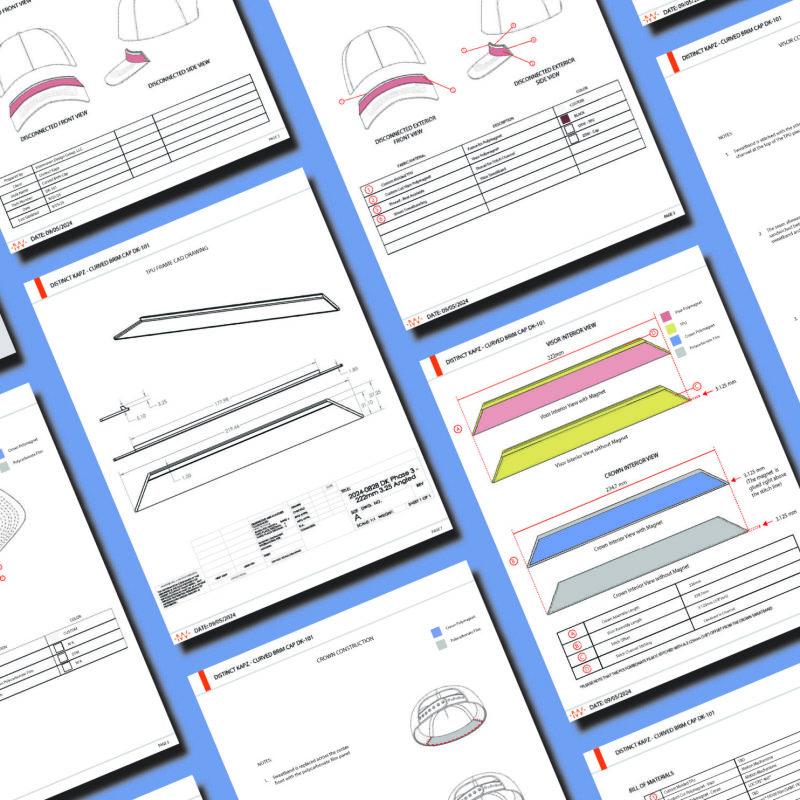

At the heart of this process is the technical design pack, or “tech pack.” It is more than just a set of drawings. A tech pack is a comprehensive roadmap and outlines exactly how a product is built, down to the smallest stitch, seam, or material choice. Without it, even the most innovative wearable or softgoods design are at risk being misinterpreted or poorly executed in production.

At Interwoven Design, we view technical design as a creative act in itself. It is a discipline that ensures ideas retain their integrity as they move from the studio to the factory floor. In this article, we outline what a tech pack includes, why it matters, and how we use it to bridge the gap between concept and creation.

What is a Technical Design Pack?

A technical design pack (tech pack) is the universal language between designers and manufacturers. It ensures that everyone—from patternmakers to production partners—shares the same understanding of how a product is meant to look, feel, and function. Think of it as the blueprint for softgoods and wearable technology. A typical tech pack includes:

- Technical Drawings & Callouts

Precise line drawings with notes on construction details, stitching, seams, hardware, and placement. - Bill of Materials (BOM)

A complete breakdown of all materials and components. It includes fabrics, foams, fasteners, sensors—required to build the product. - Measurements & Grading

Dimensions, tolerances, and size variations to ensure consistent fit across different body types or product sizes. - Assembly Instructions

Step-by-step construction methods that guide how pieces come together, whether sewn, bonded, or mechanically fastened. - Testing & Performance Standards

Requirements for durability, washability, strength, or medical-grade compliance, depending on the product category. - Labeling & Branding

Placement of logos, care instructions, or certifications that connect the product to its brand identity and compliance needs.

At its core, the tech pack is about clarity and accountability. It creates a shared framework where manufacturers know exactly what to deliver—and designers can trust the product will match their intent.

Why Technical Design Matters

Without a clear technical foundation, even the most brilliant creative concept risks breaking down in production. Technical design ensures that wearable products are not only beautiful and functional but also manufacturable, repeatable, and safe for users.

For softgoods and wearable technology, this precision becomes even more critical:

- Integration of Textiles and Hardware

A garment that incorporates sensors or mechanical components must balance flexibility, comfort, and durability. Tech packs detail how fabrics stretch, where reinforcements are placed, and how electronics are housed without compromising user comfort. - Consistency at Scale

A prototype may be hand-built with care, but manufacturers need exact instructions to replicate that quality across hundreds or thousands of units. Tech packs standardize stitching, finishes, and tolerances so every piece delivers the same performance. - Risk Reduction

By spelling out materials, testing requirements, and construction methods, technical design minimizes costly production errors and prevents miscommunication with suppliers. - User-Centered Reliability

In wearables, failure isn’t just inconvenient—it can mean loss of trust. Technical documentation ensures durability and reliability in real-world contexts, whether that’s a medical device worn 24/7 or a back-assist exosuit in a warehouse.

In short, technical design translates creativity into reality. It bridges the gap between the designer’s vision and the user’s everyday experience, ensuring that innovation holds up in practice.

Inside an Interwoven Design Tech Pack

Every product we design—whether it’s a medical brace or adaptive lingerie—requires a set of technical design assets that guide manufacturers from concept to production.

These documents are roadmaps that ensure the integrity of the design across fit, function, and user experience. This matters even more in the case studies below, where we integrate hard goods and soft goods within the same wearable. Alongside the tech pack, we create a high-fidelity mockup that serves as a companion to the technical specs, bringing them into three dimensions and demonstrating complex construction at scale.

Case Study 1: Breg CrossRunner™ Soft Knee Brace

For the Breg CrossRunner™ Soft Knee Brace, precision was non-negotiable. The brace needed to fit a wide range of leg shapes while maintaining consistent hinge placement—essential for safe, effective joint support.

Interwoven Design developed custom leg forms to represent each size, then engineered a size grading system that scaled patterns evenly without shifting key hinge locations. We created multi-layered technical drawings to capture every detail of the brace’s flaps, straps, and fabric panels. By translating these patterns into CAD and supporting the manufacturing team through sample reviews, we ensured the final product matched the vision: a premium brace that’s both supportive and comfortable.

Case Study 2: Even Adaptive Lingerie

For Even Adaptive lingerie, the tech pack became the bridge between inclusive innovation and manufacturable detail. Alongside garment design, we developed a magnetized clasp system that users could operate with one hand.

Our industrial design and garment design teams worked in parallel, using 3D-printed prototypes with embedded magnets to test usability, strength, and comfort. We documented each iteration in technical drawings and specifications so manufacturers clearly understood how to integrate the clasp into the fabric without compromising softness or fit. The result was a low-profile, reliable closure that delivered on both aesthetics and accessibility.

From Documentation to Collaboration

At Interwoven Design, we see tech packs not only as instructions for manufacturers, but as living tools. These align every stakeholder in the process, from clients and engineers to production partners. A strong pack captures the full intent of a design: the dimensions, construction methods, materials, finishes, and functional details that define how a product should look, feel, and perform. By consolidating all of this into a single, reliable reference, everyone involved—from brand stakeholders reviewing the concept to factory technicians cutting patterns—works from the same shared vision.

But we also know that design doesn’t end at handoff. Even the most detailed tech pack is only part of the equation. Manufacturing is an iterative process, and unexpected challenges can arise when ideas meet real-world production. That’s why success depends on pairing precision documentation with open, ongoing relationships with manufacturers. At Interwoven, we don’t just pass off a tech pack. We stay engaged throughout production, reviewing prototypes, answering questions, and refining details.

This collaborative approach helps bridge logistical gaps, ensures that subtle but important design decisions are preserved, and reduces costly missteps. A well-crafted tech pack minimizes guesswork, but it’s the combination of clear documentation and active partnership that guarantees the best outcomes: products that deliver on both creative vision and practical performance.

Precision as a Creative Act

Technical design is where creativity transforms into reality. The sketches, prototypes, and ideas that spark innovation become manufacturable products through careful documentation and technical rigor. At Interwoven Design, our expertise lies in creating these assets with the same care we bring to concepting and design. So, we ensure every product we hand off is made with accuracy, quality, and intent.

If you’re looking to take your concept from an idea to a market-ready product, we’d love to partner with you. With our vision and professional-grade technical documentation, we turn your ideas into fully realized products.

Interwoven Design is a design consultancy positioned at the intersection of soft goods and wearable technology. Sign up for our newsletter and follow us on Instagram and LinkedIn to learn more about design and development!