Soft Goods in Healthcare: The Human Stakes of Healthcare Design

Healthcare is about more than treating illness. While medical care focuses on diagnosing and addressing physical conditions, healthcare takes a broader view, supporting a patient’s overall wellbeing and enabling the professionals who deliver that care every day. From long hospital shifts and rehabilitation routines to outpatient care and home recovery, healthcare unfolds across environments that demand comfort, safety, efficiency, and trust.

Soft goods play a critical but often overlooked role in this ecosystem. Braces, supports, wearable devices, utility systems, and hybrid soft–hard products are in constant contact with the body, shaping how care is delivered and experienced. When designed well, they reduce strain, support movement, and integrate seamlessly into clinical workflows. When designed poorly, they can introduce discomfort, fatigue, inefficiency, or even risk. In healthcare settings, where products are worn for hours, used repeatedly, and relied upon in high-pressure situations, these details matter.

At Interwoven Design, we specialize in designing soft goods that support care beyond the clinic. Our work spans patient-facing therapeutic devices and clinician-focused tools, combining expertise in textiles, ergonomics, and integrated hard goods. By approaching healthcare design through a human-centered lens, we create products that balance clinical requirements with real-world usability, creating solutions that feel natural on the body while performing reliably in demanding environments.

In this Insight article, we explore what makes soft goods design in healthcare unique, the challenges and opportunities inherent in this field, and how thoughtful design can support both patient wellbeing and the professionals who provide care. Through real-world examples, we’ll highlight how soft goods can function not just as medical products, but as essential components of a more humane, effective healthcare system.

Why Healthcare Requires a Different Design Lens

Designing for healthcare presents a unique set of challenges that extend well beyond traditional product development. Unlike consumer or lifestyle products, healthcare soft goods operate at the intersection of physical care, emotional vulnerability, and professional responsibility. These products are worn longer, used more intensely, and trusted more deeply by patients and healthcare professionals alike.

Clinical & Operational Context

Healthcare products must perform reliably across highly controlled clinical environments and unpredictable real-world settings. Soft goods are exposed to constant movement, repeated donning and doffing, frequent cleaning, and long hours of wear. Materials must be durable, hygienic, and easy to maintain, while construction methods must withstand intensive daily use without compromising comfort or performance. For clinicians, design decisions can directly affect efficiency, safety, and physical strain during demanding shifts.

Human & Emotional Context

Unlike many consumer products, healthcare soft goods often enter a user’s life during moments of stress, pain, or vulnerability. Patients may be recovering from injury, managing chronic conditions, or navigating uncertainty about their health. Clinicians, meanwhile, work under sustained pressure, balancing precision, speed, and empathy. Thoughtful soft goods design can help reduce anxiety, restore confidence, and preserve dignity, while poorly considered products can amplify discomfort or frustration.

Regulatory & Risk Context

Many healthcare products, particularly those involved in treatment or rehabilitation, must meet strict regulatory, safety, and performance standards. Even non-regulated soft goods used in healthcare environments are influenced by infection control protocols, ergonomic guidelines, and institutional requirements. Designers must ensure that materials, construction, and interfaces are defensible, testable, and aligned with compliance standards, without losing sight of usability and human experience.

Together, these contexts make healthcare design uniquely demanding. Success depends not only on technical performance, but on an ability to understand how products are worn, moved, cleaned, trusted, and relied upon over time. It is this combination of precision and empathy that defines effective healthcare soft goods and sets the foundation for meaningful innovation in the field.

Integrating Comfort, Function, and Care

In healthcare, soft goods become part of how care is delivered. From support garments and protective equipment to clinician tools and patient mobility aids, these products sit at the intersection of the human body and complex care workflows. Designing for this space requires a dual focus: supporting the physical realities of the body while enabling the practical realities of care.

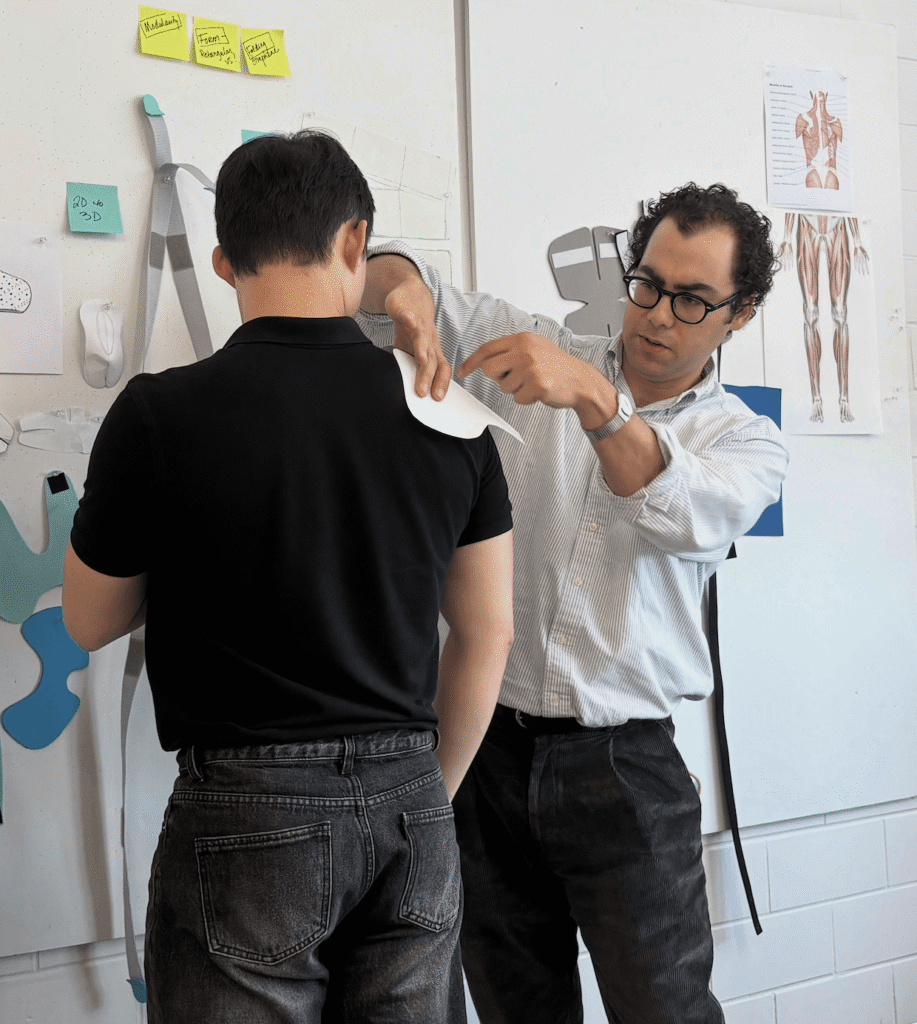

Human-Centered, Iterative Design

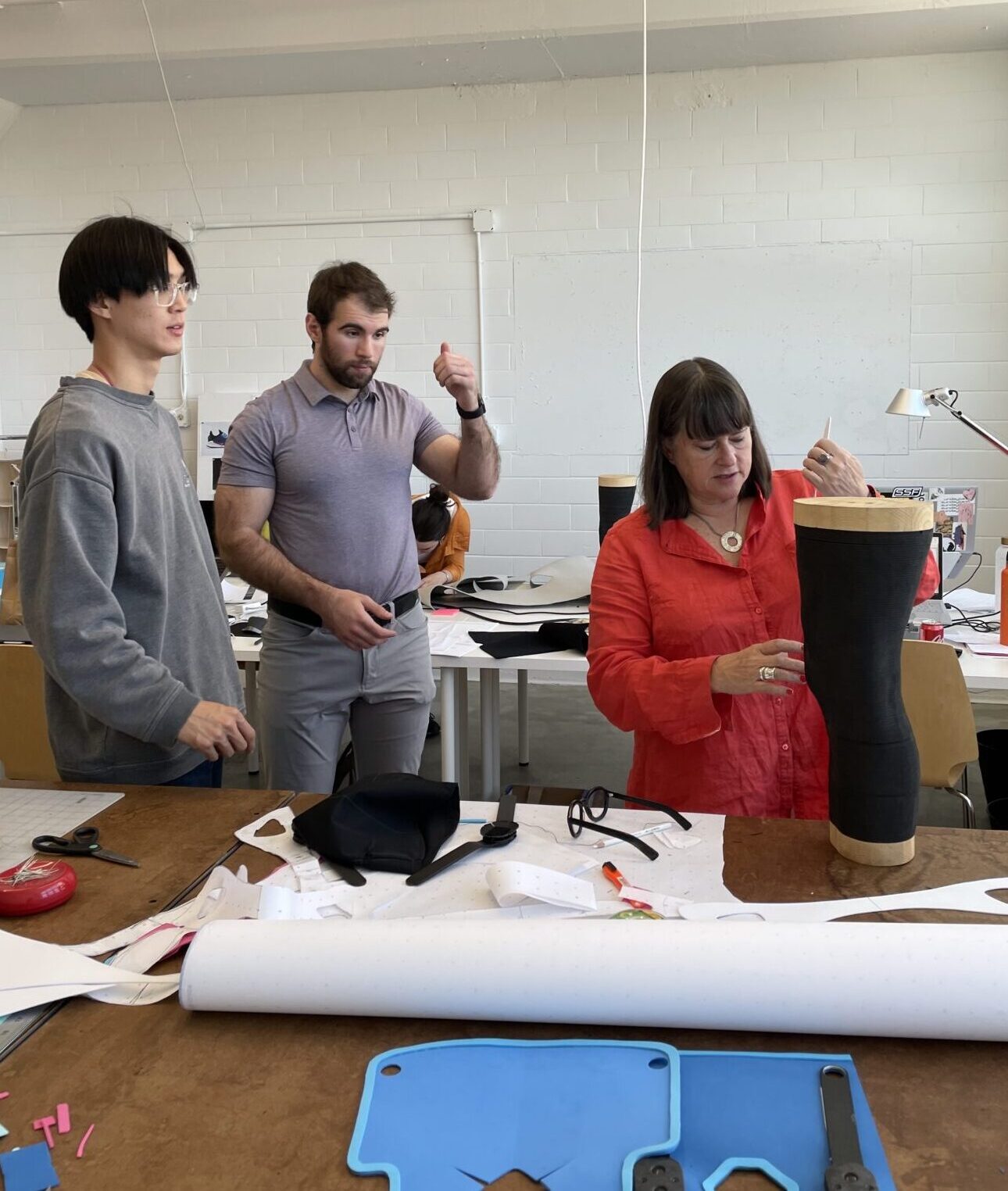

At Interwoven Design, we approach healthcare soft goods as extensions of both the body and the care environment. A brace, garment, or wearable system must accommodate anatomy, movement, and long-term comfort, while also integrating seamlessly into clinical routines. This means accounting for how products are put on and taken off, how they are adjusted, cleaned, shared, or stored, and how they perform across long shifts, repeated use, and changing patient needs. Prototyping and real-world testing are central to this process. Early concepts are evaluated not only for fit and function, but for how they behave in real care scenarios: during patient transfers, extended wear, frequent donning and doffing, or high-movement tasks.

Observing products in context reveals friction points that would be invisible in a purely technical review, informing refinements that improve usability, safety, and adoption.

Design Priorities

Material selection is always important in soft goods design, but in the context of healthcare it plays a critical role. Healthcare soft goods must balance durability with softness, breathability with protection, and structure with flexibility. Fabrics and foams must withstand cleaning protocols, resist wear, and remain comfortable against sensitive skin. Thoughtful construction helps distribute pressure, reduce heat and moisture buildup, and support natural movement, turning functional products into wearable systems that users can rely on over time.

Collaborating with Healthcare Professionals

Just as important as performance materials and ergonomic construction is designing for the people who deliver care. Nurses, technicians, and other healthcare professionals interact with soft goods in fast-paced, high-stakes environments. Products must be intuitive, efficient, and easy to integrate into existing workflows. When soft goods are designed with caregivers in mind, they can reduce physical strain, improve organization, and support safer, more efficient care delivery. At Interwoven Design, we interview and observe healthcare professionals in action in order to deeply understand their needs and their day-to-day tasks. By designing simultaneously for the body and for care delivery, we develop healthcare soft goods that support mobility, comfort, and dignity for patients while enabling clinicians to work more effectively. The result is design that fits the body while also supporting the realities of healthcare.

The Challenges of Designing for High-Impact Healthcare

Soft goods in healthcare sit at a demanding crossroads. They must perform reliably in clinical environments, remain comfortable during extended wear, and adapt to the unpredictable realities of human movement and care delivery. Unlike many consumer products, healthcare soft goods are not optional accessories, they are tools that people depend on daily, often under physical or emotional strain. As a result, long-term wearability is a key challenge. Braces, supports, and clinician-worn systems are frequently worn for hours at a time, across repetitive motions and varied postures.

Poorly distributed pressure, inadequate ventilation, or rigid construction can lead to discomfort, fatigue, or skin irritation, issues that may reduce compliance or interfere with care. Designing for healthcare means anticipating not just how a product fits at rest, but how it performs across an entire day of use.

Integration of soft and hard elements adds another layer of complexity. Many healthcare products must accommodate structural supports, sensors, fasteners, or storage components without sacrificing comfort or mobility. Every seam, closure, and interface becomes a design decision with real consequences for usability and safety. A technically sound system that feels awkward or cumbersome risks being underused, modified incorrectly, or abandoned altogether.

Hygiene and durability further shape the design landscape. Healthcare soft goods must withstand frequent cleaning, exposure to bodily fluids, and institutional laundering processes while maintaining their performance and integrity. Materials and construction methods must be chosen not only for comfort and strength, but for longevity and ease of maintenance.

These challenges represent powerful opportunities for thoughtful design. When soft goods are developed with a deep understanding of healthcare contexts, they can actively improve outcomes. Well-designed products can reduce physical strain for clinicians, support proper body mechanics, improve patient confidence, improve usage rates, and streamline daily workflows. They can also help bridge gaps between clinical settings and everyday life, supporting continuity of care beyond the hospital or clinic. For our design team at Interwoven Design, these constraints are catalysts for innovation. By balancing ergonomics, material performance, and system integration, we create healthcare soft goods that are not only functional, but genuinely supportive of the people who rely on them.

Case Studies: Design for Healthcare in Action

Healthcare design is ultimately measured in real-world use: how a product performs across long shifts, repeated motions, and moments where comfort, efficiency, and reliability directly affect care delivery. Soft goods play a critical role in how patients move, how clinicians work, and how support systems integrate into daily routines. The difference between a well-intentioned product and a truly effective one often lies in the details: fit, material behavior, adjustability, and how seamlessly a system becomes part of the body. The following case studies highlight Interwoven Design’s approach to healthcare soft goods across different contexts of care.

Case Study 1: Whitecloud Medical Utility Bag

Whitecloud Medical partnered with Interwoven Design to develop a wearable medical utility bag that directly supports the bodies and workflows of healthcare workers on the job. Healthcare professionals operate in environments defined by physical intensity, constant movement, and limited margin for error. Nurses and medical technicians routinely lift patients, transport equipment, and transition rapidly between tasks, all while carrying the tools they need to deliver care. Over time, this combination of physical strain and inefficient load carryingcontributes to fatigue, musculoskeletal injury, and reduced focus on patient care.

The Design Challenge

In clinical settings, caregivers often rely on overfilled pockets or ad-hoc storage to keep essential supplies within reach. At the same time, repeated lifting, bending, and twisting place significant stress on the lower back. Existing solutions typically addressed these issues in isolation, either offering storage without ergonomic support or back braces without functional integration into daily work routines. The challenge was to design a single, wearable that could reduce physical strain while improving access to tools without restricting movement or adding complexity during fast-paced clinical work.

Our Approach

Interwoven Design developed a modular utility system that integrates a supportive back brace with a flexible waist-mounted storage solution. The utility bag can slide along the belt for quick, one-handed access to supplies or be secured over the back support during physically demanding tasks. Both components can be detached and used independently, allowing caregivers to adapt the system to different roles, shifts, or levels of activity.

Soft goods construction was central to the design. Materials were selected for durability, comfort, and long-term wear, ensuring the system could withstand repeated use while remaining comfortable against the body. Interior organization was carefully considered, with dedicated compartments for a curated suite of medical tools, consumables, and personal items, reducing the need for overloaded pockets and minimizing unnecessary movement during care delivery.

Impact

The Whitecloud Medical Utility System supports healthcare workers where it matters most: at the intersection of physical health and daily efficiency. By combining ergonomic back support with accessible, body-centered storage, the design helps reduce strain, improve posture during demanding tasks, and streamline workflows throughout long shifts. The result is a wearable solution that not only protects the caregiver’s body but also enables them to focus more fully on their patients, demonstrating how thoughtful soft goods design can directly support the people who deliver care every day.

Case Study 2: Breg CrossRunner™ Soft Knee Brace

Breg, a leader in orthopedic bracing solutions, partnered with Interwoven Design Group to develop the next generation of their soft, hinged knee brace product line, with a focus on comfort, adaptability, and clinical performance. Orthopedic bracing plays a critical role in healthcare by supporting mobility, reducing pain, and enabling patients to stay active during recovery or long-term joint management. For individuals managing knee instability, ligament injuries, or early-stage osteoarthritis, a brace must do more than provide support, it must integrate comfortably into daily life to ensure consistent use and positive outcomes.

The Design Challenge

The challenge was to create a versatile knee brace system that could serve a wide range of patients and clinical indications, from mild osteoarthritis to a range of ligament injuries. The product needed to deliver reliable mechanical support while remaining lightweight, breathable, and easy to use. For patients, ease of donning and doffing, comfort during extended wear, and a low-profile appearance were essential to encourage adherence. For clinicians, consistent hinge alignment, predictable sizing, and clear functional differentiation across models were critical to effective prescription and fitting.

Our Approach

Interwoven Design worked closely with Breg’s internal engineering and manufacturing teams to develop a cohesive, patient-centered brace system. Early concept development focused on understanding user interaction with the brace: how it feels to put on, adjust, and wear throughout a full day of movement. Mood boards and design research established a visual and functional language rooted in anatomy, clarity, and ease of use.

Through 2D sketching and 3D foam mockups, the team explored compression zoning, material placement, and hinge positioning to balance stability with comfort and thermoregulation. The resulting CrossRunner™ line features four configurations—wraparound, pull-on, long, and short—ensuring that clinicians can select the most appropriate solution for each patient’s anatomy, condition, and lifestyle.

Soft goods design was central to the brace’s performance. The body of the brace utilizes Breathefit™ fabric, combining neoprene and Airmesh® to deliver therapeutic compression while maintaining breathability during extended wear. A sleek, low-profile hinge with customizable range-of-motion stops allows clinicians to fine-tune support while preserving a streamlined, wearable form. Interwoven also designed key user-facing elements including strap configurations, hinge covers, tabs, bindings, branding, and colorways; details that improve usability, durability, and overall patient experience.

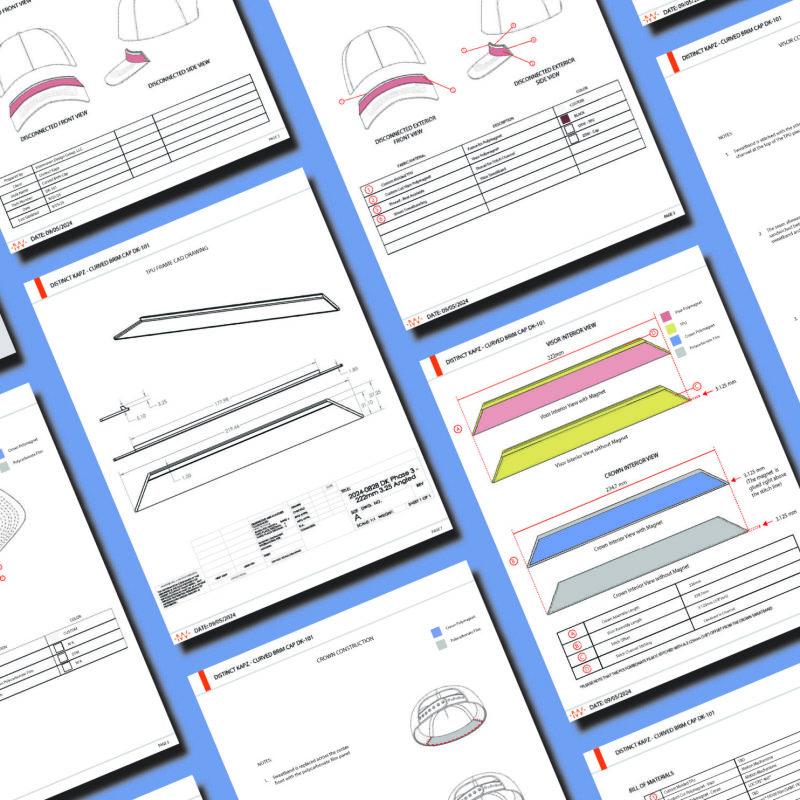

Technical Development and Production Support

To ensure accurate fit and clinical reliability, Interwoven collaborated with Breg to develop custom leg forms representing each brace size and led the size grading process across eight distinct sizes. Technical patterns were engineered to maintain consistent hinge placement across diverse leg shapes, a critical factor in brace effectiveness. Detailed CAD drawings and technical documentation clearly communicated material layers, strap alignment, and construction details to Breg’s manufacturing team.

Interwoven remained engaged through sampling, refinement, and production, supporting quality control and ensuring the final product met both clinical and manufacturing standards. This ongoing collaboration helped translate design intent into a scalable, high-quality medical product.

Impact

The Breg CrossRunner™ Soft Knee Brace delivers a patient-centered solution that supports mobility, comfort, and confidence throughout recovery and daily activity. By combining precise orthopedic function with thoughtful soft goods design, the brace encourages consistent wear, which is an essential factor in achieving positive clinical outcomes. For healthcare providers, the cohesive product line simplifies fitting and prescription, while offering adaptable options for a wide range of conditions.

Designing Systems of Care

Healthcare extends beyond the treatment of illness. It encompasses the everyday systems that support wellbeing: comfort during long hours, mobility through recovery, efficiency in demanding environments, and emotional reassurance in moments of uncertainty. While medical care often focuses on diagnosis and intervention, healthcare design must account for the lived experience of both patients and the professionals who care for them. This is where soft goods play an essential, and often underappreciated, role. A knee brace is not just a product; it is part of a recovery process. A utility bag is not just storage; it is a mobile workstation for a nurse navigating a twelve-hour shift.

Soft goods function as the quiet infrastructure of healthcare. When designed well, they fade into the background, supporting movement, reducing strain, and enabling care without calling attention to themselves. When designed poorly, they become barriers: restricting motion, causing discomfort, or adding friction to already complex workflows. Their impact may be subtle, but it is deeply felt across long shifts, repeated use, and extended recovery periods. Every design decision must account for a complex web of users, environments, and expectations.

At Interwoven Design, we believe healthcare products should work with people, not against them. Our approach centers on designing systems that support care teams, protect bodies, and respect the physical and emotional realities of healthcare environments. By integrating soft goods expertise with human-centered thinking, we create solutions that align performance with comfort, structure with flexibility, and durability with dignity.

We collaborate with healthcare innovators, medical companies, and care organizations who recognize that better care is built through thoughtful design. Together, we design soft goods that elevate care delivery, strengthen wellbeing, and improve the human experience at every point of contact.

Interwoven Design is a design consultancy that is positioned at the intersection of soft goods and wearable technology, creating products that function with the body and offer comfort as well as the superb performance that arises through the innovative incorporation of rigid, often electronic and responsive elements. Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!