Tried and True: Validation and Testing in Soft Goods Wearable Technology

Why Testing Matters

In wearable technology, ideas don’t just live on a screen or in a prototype, they live on the body. That means every design decision, from the angle of a strap to the stretch of a textile, directly impacts how a product feels, functions, and performs in real life. Unlike hard goods, where performance can often be validated through digital simulations or mechanical testing, soft goods require a different level of scrutiny. Comfort, fit, and durability can’t be fully predicted without real-world testing.

At Interwoven Design, we see testing not as a final checkbox before launch, but as an essential part of the design process. It’s how we uncover the subtle issues that CAD files and sketches can’t reveal: a seam that rubs after an hour of wear, a closure that feels intuitive in theory but awkward in practice, or a textile that stretches beautifully in the lab but loses integrity after repeated washing. Testing is how we build confidence in the products we design; for our team, for our clients, and most importantly, for the people who will rely on them. In this Insight article, we’ll outline what’s unique when testing soft goods, testing techniques we use in our studio, the process developing test protocols, and share three case studies that demonstrate the value of testing in wearable tech.

What Makes Soft Goods Testing Unique

Testing soft goods isn’t just about checking boxes on durability or performance, it’s about validating how a product interacts with the human body. Unlike rigid products, soft goods flex, stretch, and conform, which means the variables multiply. A harness may perform well on one body type but dig uncomfortably into another. A fabric might wick sweat effectively but lose breathability once layered. Even something as subtle as a seam placement can make the difference between a product that feels effortless and one that users abandon. These nuances make testing in soft goods especially critical.

Comfort, ergonomics, and wearability can’t be fully captured by digital modeling or static evaluation. They need to be worn, adjusted, and lived in. At Interwoven Design, we approach testing as both technical and human centered: technical in measuring durability, strength, and performance; human-centered in evaluating comfort, fit, and user experience over time.

The challenges are amplified when technology is integrated. Wearable sensors, power sources, and connectivity components add complexity to already delicate material systems. Ensuring that a textile stretches without disrupting circuitry, or that an engagement mechanism is positioned intuitively, requires iterative testing at every stage. Add to this the reality that soft goods often need to fit a wide range of body types, movements, and environments, and you get a testing landscape that is both demanding and essential.

This is why testing isn’t an afterthought for us, it’s a design driver. By confronting these challenges head-on, we can refine products so they’re not only functional in theory but reliable, comfortable, and intuitive in the real world.

Types of Testing We Use

At Interwoven Design, we see testing as a layered process. Each stage answers a different question: does it hold up, does it feel right, does it work in the real world? By combining technical evaluation with lived experience, we create products that are both reliable and human-centered. Each type of testing reveals different insights, and together they form a comprehensive validation process.

1. In-House Testing as a First Line

Before we send prototypes into the field, we stress-test them in the studio. In-house testing allows our team to push early concepts to failure, observe weak points, and refine design elements quickly. This controlled stage saves time and resources by filtering out obvious flaws before involving external testers or clients.

2. Ergonomic & Fit Testing

Comfort and wearability are non-negotiable for soft goods. We run structured fit trials across diverse body types, tracking everything from pressure points to range of motion. These insights ensure the product adapts to real human variation, not just a single “ideal” model.

3. Durability & Material Testing

From fabric abrasion to seam strength, we evaluate how a product holds up under repeated use. We also test environmental performance—exposing prototypes to heat, humidity, or repeated laundering to anticipate how they’ll age over time. For wearable technology, we also look at how embedded electronics and hardware behave under repeated strain, ensuring sensors, circuits, and connectors remain reliable as materials bend and stretch.

4. User Experience Testing

The most rigorous test is the target audience wearing and interacting with the product. We work closely with end users—nurses, athletes, warehouse workers, patients—to gather qualitative and quantitative feedback. We study ergonomics, comfort, ease of use, and long-term wearability, while the users execute the body movements typical for the wearable, iterating prototypes based on their lived experience. Small adjustments, like repositioning a seam to bolster support or refining adjustability for greater control, can transform acceptance and adoption rates.

Functionality doesn’t stop at fit and durability. We observe how users actually interact with the product in context—how quickly they can don and doff it, how it integrates into workflows, and how intuitive the design feels. These behavioral insights are critical for adoption.

5. Field Testing

Soft goods live in unpredictable environments, so testing them in context is essential. Whether it’s a warehouse, hospital, or outdoor trail, we evaluate products in the environments where they’ll actually be used. This allows us to track how sweat, weather, temperature, or prolonged wear affect performance. Field testing often reveals subtle issues, like unexpected environmental conflicts, that lab conditions can’t replicate.

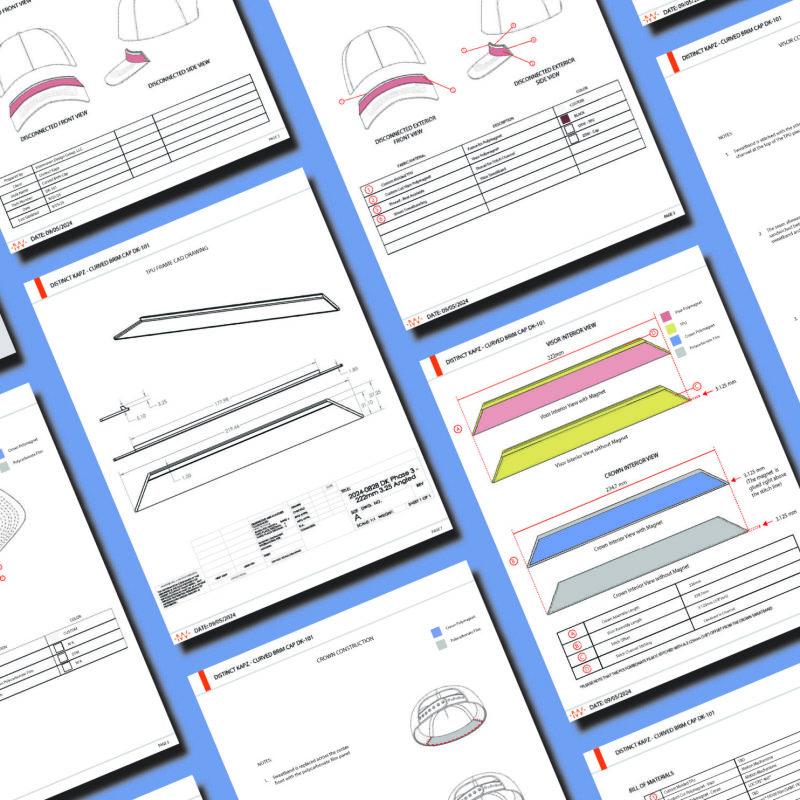

Developing Test Protocols

No two soft goods projects are alike, and neither are their testing needs. A performance-driven backpack, a medical compression garment, and a wearable sensor system all demand different metrics of success. That’s why at Interwoven Design, we don’t rely on one-size-fits-all checklists. Instead, we collaborate with clients to build test protocols that are tailored to their product, user base, and market context.

The process starts with clarifying priorities: Is the primary concern comfort during extended wear? Durability under heavy load? Compliance with medical or industrial safety standards? From there, we map testing methods to those goals. For example, a healthcare wearable may require protocols aligned with regulatory requirements, while an industrial soft good might emphasize stress testing, longevity, and performance under extreme conditions.

Equally important is balancing quantitative and qualitative feedback. We often combine lab metrics (such as tensile strength or moisture resistance) with user-centered data (comfort, usability, ergonomics). Together, these insights give clients a clear, evidence-based picture of how their product will perform in the real world. By developing test protocols alongside clients, we create not only a validation process but also a shared language. This ensures alignment early, reduces the risk of missteps later, and ultimately results in products that meet both technical standards and human needs.

Case Studies: Testing in Action

Case Study 1: Project Firefly — Validating Reflective Durability

When Red Kap approached Interwoven Design to develop Project Firefly, a new line of reflective Type O workwear garments, one of the most pressing challenges was durability. Reflective materials are essential for worker safety, but in warehouse and industrial settings they face harsh conditions: constant friction from movement, contact with equipment, and repeated exposure to industrial laundering. A material that looked promising on paper could easily fail once subjected to the realities of the job site.

To address this, we incorporated abrasion testing early in the design process. Using our testing methodology, we simulated the high-friction scenarios workers regularly encounter—lifting, bending, kneeling, and brushing against rough surfaces.

By evaluating reflective materials under these stresses, we were able to pinpoint which options maintained their integrity and visibility over time. This testing didn’t just confirm durability; it also informed design decisions, such as strategic placement of reflective elements to minimize wear while maximizing visibility.

The result was a set of garments that met the highest safety standards while withstanding the rigors of warehouse conditions. Abrasion testing proved to be a critical step in validating that the reflective components would perform reliably over the lifespan of the garment, giving both workers and employers confidence that safety would not degrade with use.

Case Study 2: Even Adaptive — Testing for Intuitive, One-Handed Use

For Even Adaptive, Interwoven Design set out to reimagine adaptive lingerie by creating garments that could be put on with the use of a single hand. Unlike traditional lingerie closures, which are often difficult or impossible to manage without two hands, this line demanded a design solution that was not only functional but also elegant, comfortable, and inclusive. At the heart of the project was the development of a custom magnetic clasp; a new closure system designed to empower women with limited mobility while offering a contemporary, stylish alternative to the outdated adaptive lingerie on the market. From the start, our delivery team knew that validation with the target audience would be key to our process.

We conducted testing sessions with women who had the use of only one hand, observing how they interacted with prototypes and gathering real-time feedback. This ensured that the clasp design, garment construction, and finger-loop supports were intuitive, reliable, and easy to operate under everyday conditions. In-house testing confirmed magnet strength, clasp durability, and comfort against the skin, while user trials revealed small but critical refinements—such as adjusting clasp engagement force and loop placement—that made the product seamless in practice.

The result is a line of adaptive lingerie that feels both functional and beautiful, bridging accessibility and style in a way that had not existed before. The success of this validation-driven design process was recognized at the highest levels: Even Adaptive won the Professional Award in the Personal Accessories category at the 2023 Core77 Design Awards and was named an Honoree in Fast Company’s Innovation by Design Awards, Accessible Design category. These accolades affirm not only the product’s innovation but also the importance of rigorous, user-centered testing in bringing meaningful, inclusive solutions to market.

Case Study 3: SABER Military Exosuit — Field Testing for Real-World Performance

Developing the SABER Military Exosuit for the U.S. Army required more than theoretical models or lab simulations. To ensure the exosuit could meet the demanding physical and operational needs of soldiers, Interwoven Design partnered closely with Vanderbilt’s Zelik Lab and conducted extensive field testing with the 101st Airborne Division at Fort Campbell. Observing soldiers in their natural work environment allowed the team to understand not just lifting movements, but the full range of activities—including carrying gear, navigating obstacles, and performing operational tasks—that the exosuit would need to support without restricting mobility.

Through iterative prototyping and in-field trials, we validated key aspects of the design, from the placement and tension of elastic bands to the comfort of shoulder straps and thigh sleeves over long periods of wear.

Soldiers provided real-time feedback on range of motion, heat retention, and overall ergonomics, enabling the team to refine materials, adjust fit, and improve the ease of donning and doffing.This continuous feedback loop was essential in creating a lightweight, breathable, and low-profile exosuit that successfully reduced back strain while remaining unobtrusive in active duty scenarios.

The results were compelling: the SABER exosuit, weighing just 2.7 pounds, reduced over 50 pounds of back strain per lift and improved overall endurance and performance in demanding tasks. Field testing confirmed that the design was intuitive, comfortable, and effective for extended wear, demonstrating how rigorous validation with the target audience is crucial for wearable technologies, particularly those intended for extreme or high-stakes environments.

Building Confidence Through Testing

At Interwoven Design, testing is more than a checklist, it’s a mindset. It embodies curiosity, validation, and iteration, ensuring that every concept not only works but feels intuitive, comfortable, and human-centered. Rigorous testing allows ideas to evolve from sketches and prototypes into products that perform reliably in real-world conditions, whether that means a reflective workwear garment, adaptive lingerie, or a wearable exosuit for military or industrial use.

Validation reduces risk, inspires trust, and ultimately delivers better outcomes for both users and clients. By engaging with testing early and often, Interwoven ensures that products meet functional, ergonomic, and experiential goals before they reach production. Far from being a hurdle, testing is a powerful tool for innovation; a way to explore possibilities, uncover hidden challenges, and refine solutions with confidence. Prospective clients are invited to collaborate with Interwoven to develop tailored test protocols that align with their vision, needs, and user requirements, transforming ideas into products that are not only effective but also thoughtfully designed for real human use.

Interwoven Design is a design consultancy that is positioned at the intersection of soft goods and wearable technology, creating products that function with the body and offer comfort as well as the superb performance that arises through the innovative incorporation of rigid, often electronic and responsive elements. Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!